Metal Wall Panel Repair and Replacement

Metal Wall Panel Services

Elevate the structural integrity and aesthetic appeal of your pre -engineered metal buildings with our comprehensive line of wall panel services. Our team expertly addresses issues related to metal wall panels, offering solutions for repairs, replacements, and enhancements. Our dedicated team delivers exceptional results on both large-scale transformations and small-scale projects.

Complete Metal Wall Panel Replacement

Full wall replacement represents a comprehensive solution to elevate the functionality and appearance of industrial buildings. Whether due to extensive damage or a desire for a modern aesthetic transformation, our expert team specializes in seamlessly executing complete wall replacements. Beyond restoring structural integrity, this service opens the door to a fresh aesthetic look. We understand that updating panels isn’t merely about repairs but an opportunity for a design upgrade. Our replacement services ensure that your industrial building not only regains its structural robustness but also emerges with a renewed aesthetic appeal. It’s not just a repair; it’s an opportunity to transform your building.

Before: A complete wall panel replacement in Sugarland, TX. The worn out wall panels needed a complete replacement. We replaced the aging Monarch/Vista panels.

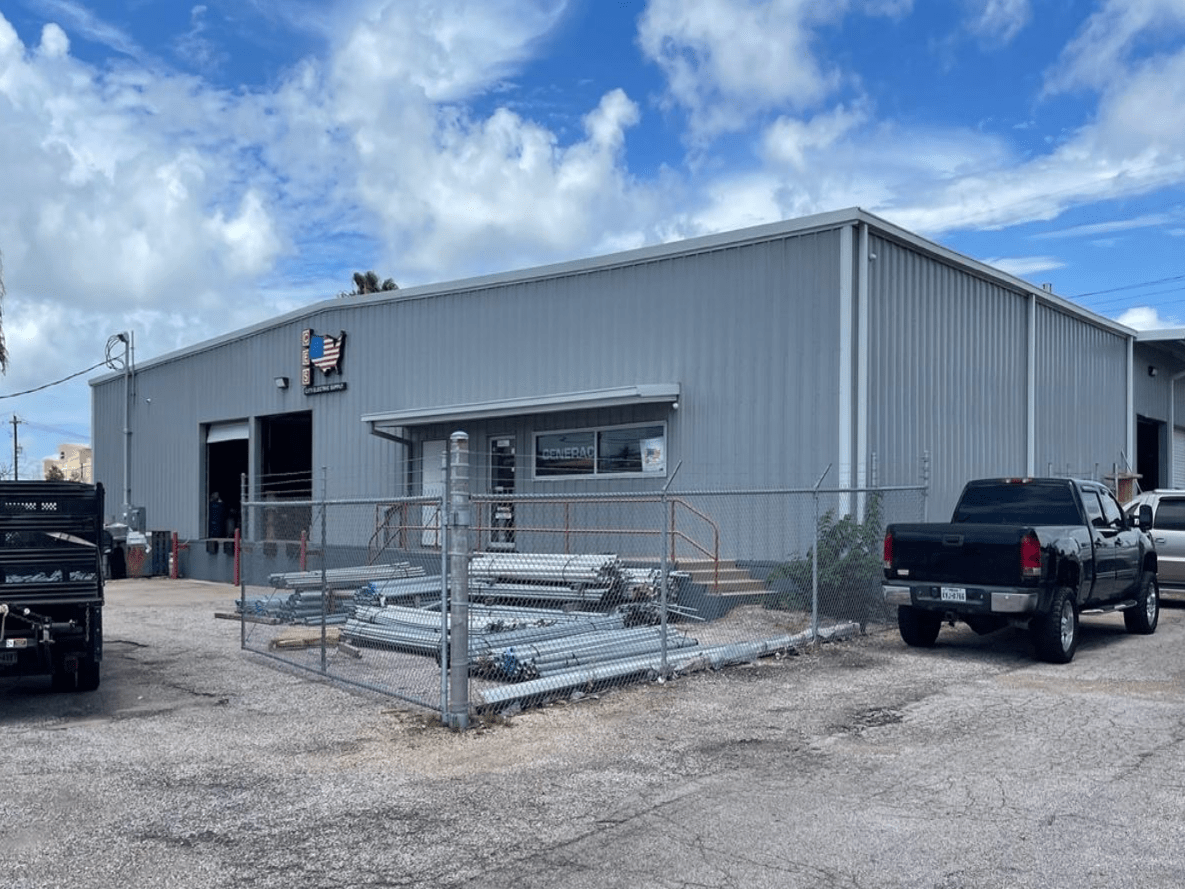

After: We replaced conventional exposed fastener wall panels with two types of hidden fastener wall panel systems, one with a textured finish, and a horizontal galvanized panel for a striking contrast.

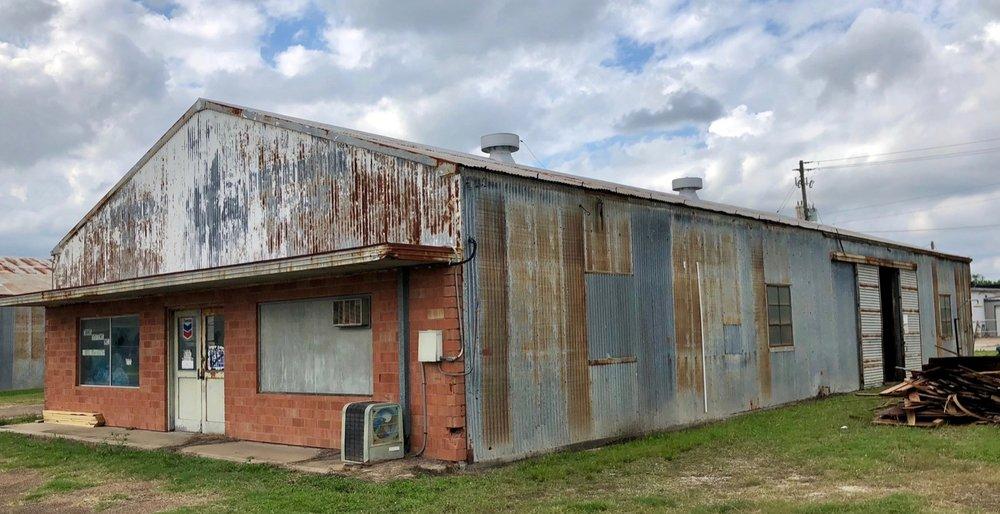

Before: Metal building before the rusting metal R panel roof and walls were replaced. This metal building has good structure, it just needed panels. The building needed the rusting metal wall panels and rusted metal roof panels repaired.

After: A showcase building with a new metal roof, replaced wall panels, and framed out with a newly installed overhead door.

Before: A metal commercial building in Sugarland, TX.

After: An upgraded commercial look. We build a parapet cap 5′ from the building and installed hidden faster panels.

Before: Metal building in in Galveston, TX

After: An R panel installation project. Our team replaced the wall panels and painted the building.

Metal Wall Panel Cut and Paste Repairs

Cut-and-paste wall panel repairs are a strategic and efficient solution for addressing localized issues in metal wall panels without necessitating a full replacement. This technique involves carefully cutting out the damaged or deteriorated section of the panel and seamlessly pasting or welding in a precisely fitted replacement. This targeted approach is particularly advantageous when dealing with isolated damages, such as impact damage, scratches, or localized corrosion.

One of the primary benefits of cut-and-paste repairs is cost-effectiveness, as it allows for the preservation of the majority of the existing panels, minimizing material and labor expenses. This method also contributes to reduced downtime during repairs, making it an attractive option for businesses and industrial facilities where operational interruptions need to be minimized.

Do I have to replace all of my metal wall panels?

Thats up to you! Frequently, our customers save money with cut-and-paste metal wall panel replacements vs. a complete panel replacement.

Why should I choose a cut and paste panel repair?

Cut and paste repairs are cost-effective solutions that minimize operational downtime and expense.

Should I paint my wall panels or replace them?

Painting rust at the base of your buildings wall panels won’t help. Good paint will last 5 to 7 years, but new wall panels will last 20 to 40 years (depending on your environment).

A cut and paste wall panel repair. Our team cut out the bottom 7′ of the damaged panels. We installed horizontal trim to define the old and new panel areas. The trim worked well enough that painting the old panels was not required, saving the building owner money.

The bottom of the metal building wall panel was rusted out and pushed out on this airport hangar. The bottom 4′ of metal wall panel, base angle and insulation were replaced. This was much more affordable than replacing the entire panel.

Rusted Wall Panel Replacement

Rusted panels can compromise the aesthetic appeal of your building and impact its structural integrity. At Metalguard, our dedicated team of experts is committed to seamlessly replacing those corroded panels, breathing new life into your space. Beyond restoration, our services offer a chance to redefine the look and feel of your property, ensuring that durability meets design.

Before: Metal building rusting wall panels before being replaced with a hidden fastener panel system.

After: Metal building wall panels after a replacement was completed.

Before: Metal building rusting wall panels before being replaced with a hidden fastener panel system.

After: Metal building wall panels after the replacement was completed.

Wall Panel Damage Repairs

Frequently wall panels and doors are damaged at commercial sites and warehouses. Our team can help with quick repairs. For this repair a truck damaged the bollard (and concrete base), the overhead door and wall panel. We replaced them all. Our cement crew repaired the cement and installed the bollard.

On the left is the picture of the Cee channel that was pushed back an inch, wall panel and trim damage. This shows after the bollard and concrete repair, but before the steel repair.

On the right is the After picture of the necessary repair due to damage to the wall from a semi–truck

Our Team in Action

Metalguard has been repairing pre-engineered metal buildings for over 25 years. Our detail-oriented team designs custom solutions for each job. For this project, the Metalguard team repaired this metal building. The bottom 7 feet of the metal panels were rusting out, and the windows were at the end of life. Our team replaced the metal wall panels, replaced the base angle, added insulation, and replaced the windows. Finally, we added a piece of metal trim to define the top and bottom, giving the building a sharp finished look.

Wall Replacement Overview - Panel Options

Metalguard is a metal contractor with it principal focus on the repair of metal buildings, including the primary steel structural, secondary steel components, panels, attachments (awnings, lean-to’s) insulation and the concrete pad. The following panel options are presented in the context of repairing an existing metal building.

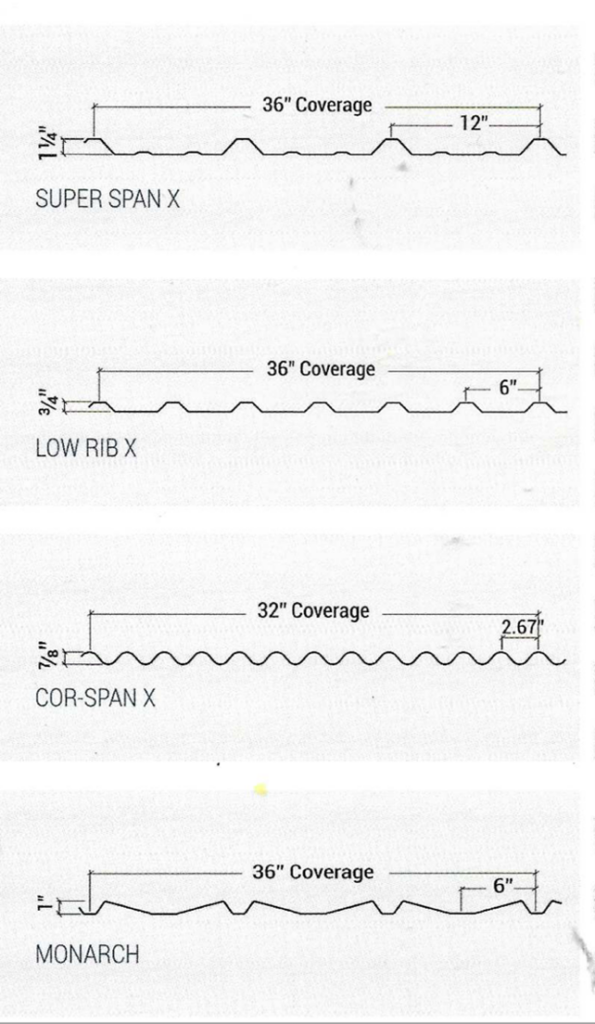

Super Span X – Also called a R panel or PBR panel. Is the most common metal panel. Used on walls and roofs.

Low Rib X – This panel is also known as a U panel. Different manufactures have different names. Less common than an R panel. The lower profile and different high rib pattern provide a different look than the R panels because of the shadow it produces.

COR-SPAN X– also called a corrugated panel, is common in agriculture applications. It has often been used on the roof in barns – but because there isn’t a flat section for a fastener’s rubber washer to seal to, it’s not a good roof waterproofing panel. But because of its different look, it is sometimes seen as an accent wall panel.

MONARCH – This is also referred to as a V panel or AVP panel. It is a wall panel only. The top of the picture is the outside. The profile gives the wall a different look then the others. It was most common in the 80 and 90’s.

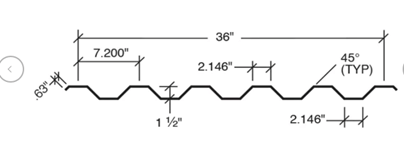

Hidden Fastener Panel

Metal Building Complete Wall Replacement

Below – A standard metal building renovation process. We replaced the roof and walls with new metal panels.

During the process of the replacing the roof and walls this building was not in use. By stripping off the old panels and then re-installing them without having to close up and make the building watertight every night we saved the building owner a little money. During the process we found 12 roof purlins requiring replacement and also had to replace 7 wall girts. The building had a paint booth in it before with liner panel – we left that in place on the left side of the roof. The new building had insulation added plus R panels for both the roof and the walls.