Metal Building Roof Repairs and Replacement

Expert Inspection and Custom Solutions

Metal Roof Repair Project

On this project, the Metalguard team replaced sections of the metal roof panels and installed new skylights on a 192,000 square ft metal building. See below for interior and exterior photos and a video flyover of the project. On the right is an aerial shot of the project. Replacing the building with new metal roof panels and skylights will extend the life of this building and fix the leaks. On the left is an interior view of the project with new metal roof panels and skylights that are installed on the right-hand side.

A video of the Metalguard team on top of the roof, replacing the metal roof panels.

Metal Roof Projects

Before: This old metal roof was leaking in multiple places. Our team replaced 48,000 square feet of metal roof panels.

After: We installed new panels and an internal gutter and conducted leak testing to ensure the integrity of the new roof.

Before: This metal building renovation took place in Texas City, TX. During the project, our team replaced 7 steel roof purlins, 3 eave struts and 4 steel wall girts. All metal roof panels were replaced, and we installed new trim. New insulation was added to improve the cooling performance of the metal building.

After: To facilitate repairs, the team had to safely remove the roof stacks. Our customer was extremely satisfied with the repairs and the long-term value added to their metal building.

Before: An old metal warehouse before a metal roof replacement. One of the many benefits of replacing a metal roof is that the insulation is typically replaced or added during the project. A replacement of the metal roof and walls allowed for new insulation during the metal roof replacement.

After: Completed metal roof replacement with new insulation. We installed a new metal roof with new insulation. The new insulation actually made the building smell a lot better. We removed a lot of mold growing in old wet insulation. We also installed all-new EPDM rubber boots for all of the vents coming out of the roof.

Before: Metal roof replacement before picture. This metal building was used for storage before. One of the other nice features of a metal roof replacement with new insulation is a new clean smell.

After: Metal roof replacement after picture. We were almost finished with the replacement, the trim needs to be installed, and the clean-up is to be done, but you can see the difference. During the process, we also cleared and painted the purlins, moved some walls, and added some overhead doors. Whatever is on your to-do list. We even had a new floor coating applied before we were finished.

Metalguard’s Team in Action

The Metalguard team installing new metal roof panels.

Metalguard’s Team in Action

An exterior view of the Metalguard team working on the project. The team is replacing metal roof panels and installing new skylights.

Roof Leak Fixing

This metal roof was leaking, so to fix the issue, we sealed the lower metal roof and upper metal roof. First, because of a previous coating, we installed a larger amount of new material to cover the old material. Then, on the rest of the existing metal roof panels, our team sealed the fasteners.

The photos show the repaired metal roof. The light-colored areas are new metal roof panels, and the white dots are sealed fasteners. Replacing where necessary and repairing the rest of the roof represented the best value for the client.

Metal Roof Replacement Process

Metal roof replacement with new insulation installed, increasing R-value & providing a flat surface for the metal roof panel to be installed over the shingled roof. Foam closures that conform with the panel profile are added at the ridge cap & at the eave. These keep birds, small animals & insects out, in addition to water.

The walking path allows for service staff to walk on the roof safely & to protect the roof against foot traffic damage. This completed metal roof installed over shingles should last 40 years. There are many types of metal roof profiles to choose from; standing seam, screw-down pbr panel, U panel, & many others.

Metal Roof Replacement

Replaced Industrial Roof

Quality Standards and Renovation

Installing a Metal Roof Over an Existing Metal Roof

Is your metal roof beyond repair, and it’s not practical to replace your roof?

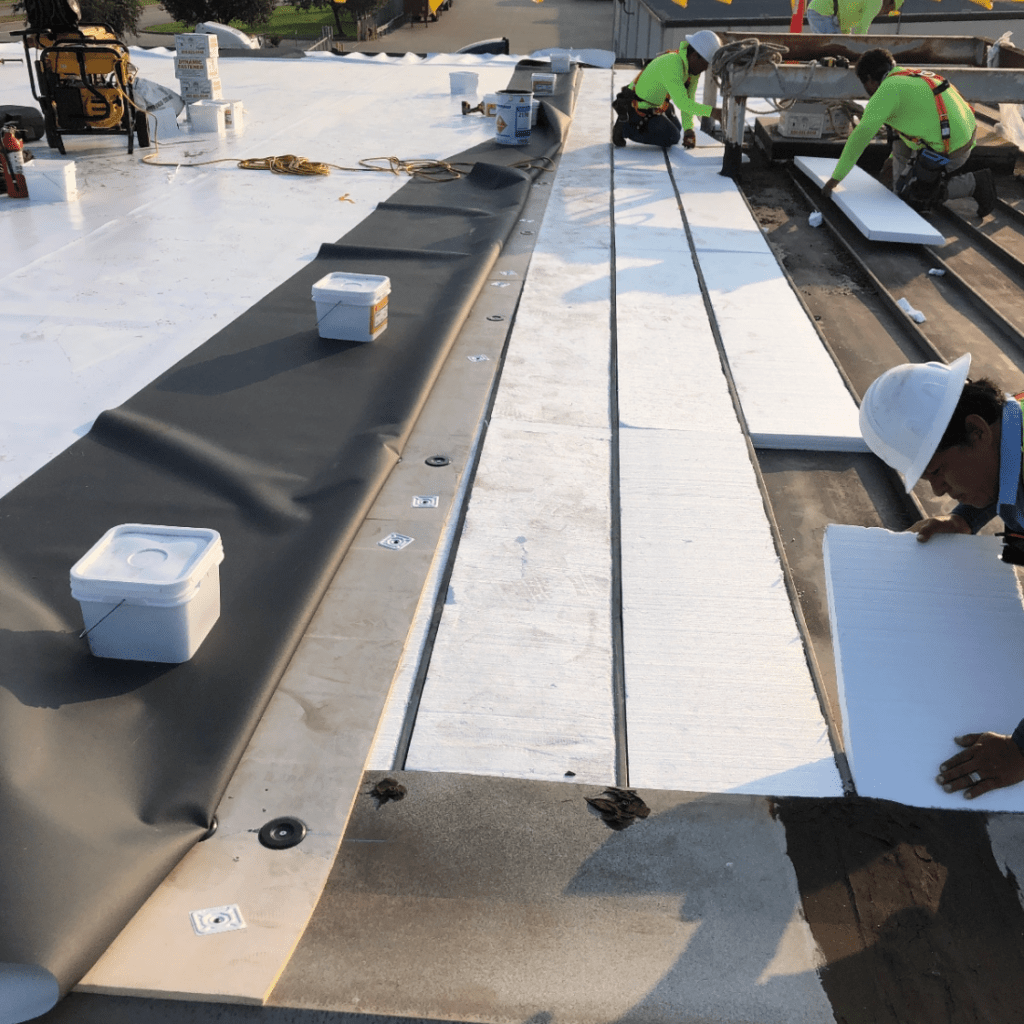

Install a new metal roof over your existing metal building roof. Sometimes when repairing a metal roof on a metal building, the customer can’t have any interruption in their business, but the roof is too far gone for a coating. That’s when a membrane roof might be the right solution. as it was here.

Metal Roof Leak Repair

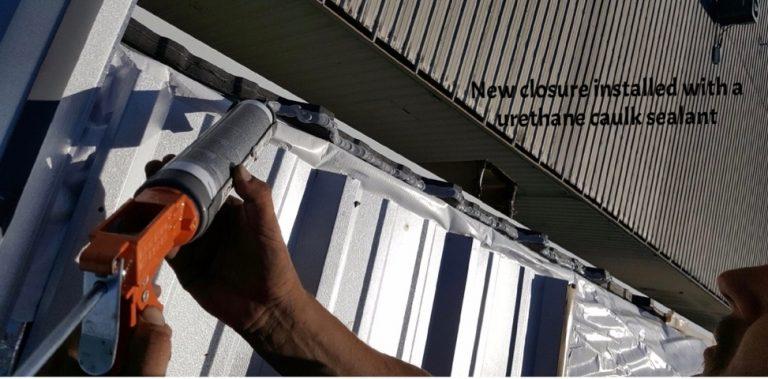

Metal roofing leak repair – Metal roof cut and paste due to Metal roof leaks at the eave, or the edge is due to failed closures or the lack of closures.

Metal roof cost and paste before picture. Met building roof panel that were rusted out at the eave. Eave leaks on a metal roof due to failed closure. Leaks along the edge, or eave, of a metal roof is extremely common. It is due to improper installation failure of closures at the eave between the bottom of the roof panel and the eave strut. As part of our repair process we follow Metalguard repair procedures. We seal the metal roof eave to prevent this from happening in the future.

The reason the metal roof panels rot out at the eave of the roof is because the metal building insulation gets wet. It stays wet ant rusts out the underside of the roof panel. All because of improper eave detail.

Metal roof leaks at the eave of a metal roof. Closure was never installed and water backed up from the gutter under the roof panel keeping the insulation wet. The bottom is always rusted out more than the top.

If closures are not installed, as they were not in the above picture, water can back up between the bottom of the roof panel and the eave strut, which is the part of the steel structure of a metal building where the metal roof panels are fastened to at the eave. It is common for the insulation to be folded back to keep water from entering the building.

The problem is the insulation vinyl facing starts to dry out, it becomes brittle and delaminates. The fiberglass insulation starts to hold water and starts rusting the roof from the bottom. The rusting starts at the holes in the roof made by the eave fasteners. It won’t leak at first, unless its a very heavy rain, but the roof is being damaged.

Metal building leak repair – metal roof cut and paste. The old panels were removed along with the damaged insulation and new closures were installed and sealed. Just the damaged parts were replaced – a cut and paste repair. The old panels were removed along with the damaged insulation and new closures were installed and sealed. Just the damaged parts were replaced – a cut and paste repair.

The rusted metal roof panels at the eave on this rusty leaking metal roof were cut out and replaced with new matching metal panels. The seams where the old and new panels were joined were sealed using butyl caulk tape between the panels. This provides a long term water tight seal. In addition to the rusted thru eave panels, all other panels found to be beyond repair on the roof were replaced. Houston, TX

Below: This metal roof section had been sealed many times in the past. It really needed to be replaced, there were holes in it.

After: This metal roof cut and paste completes the leak stopped.

Below: The owner wanted metal roof skylight of the building removed. We took the initiative by removing a raised skylight panel in a standing seam metal roof and replacing with metal standing seam panels.

After: Removing a raised skylight on a standing seam metal roof and replacing it with a metal roof panel including insulation.

Our Work Portfolio