Structural Engineering

Repairing a Column in a Metal Building in Angleton TX

Overview – Location: Angleton TX. When the new owner purchased this building, they were very aware that repairs were necessary.

A list of the required repairs was prepared, priorities were set.

A structural engineer started working on the necessary structural repair plans for the columns.

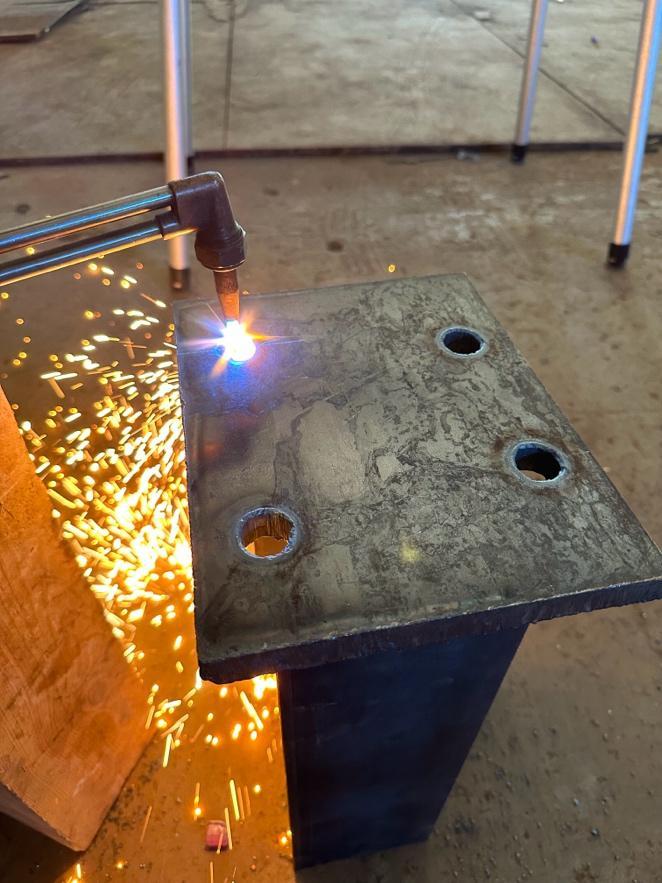

First project: repair the damaged columns. First step: Inspect the columns, identity damage, create engineered repair plan, and then execute. Pictures and descriptions below.

The picture on the right shows the column design. Dual column, one of the columns is tapered.

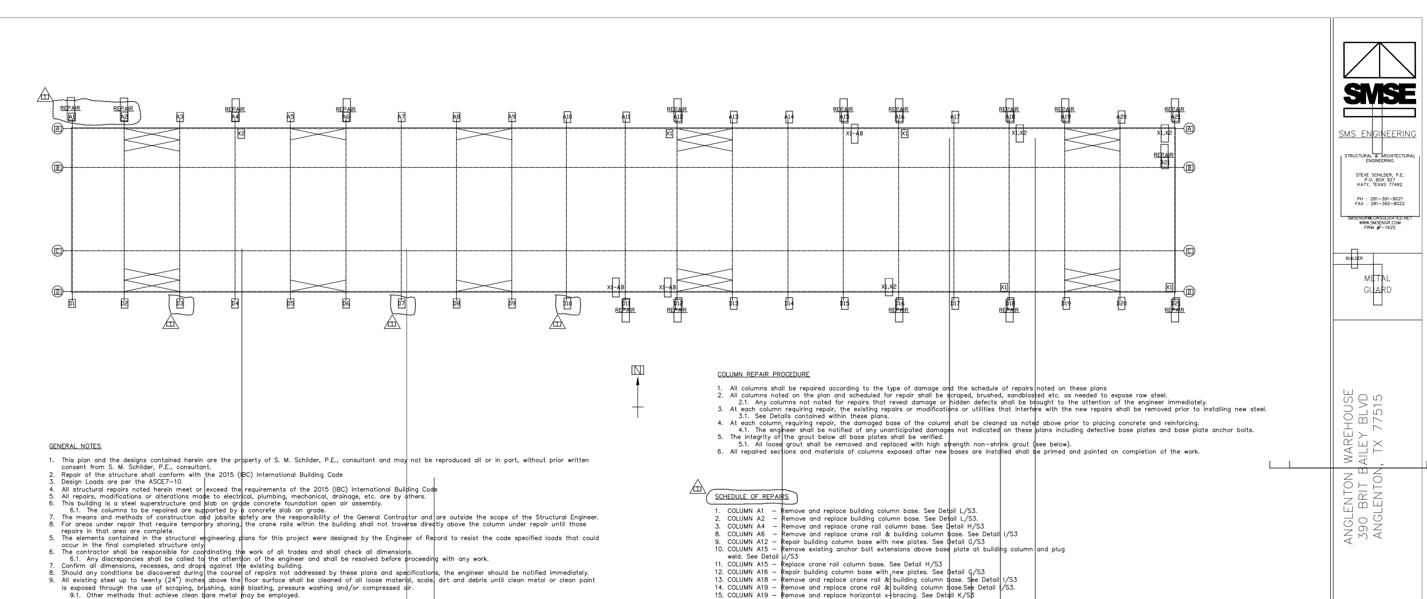

For this project, an engineering firm was engaged. The engineers inspected each column, 48 areas that had 84 posts total (two posts along the sides).

Below are two sections of the plans, an outline of the building and detailed repairs.

Based on the inspection and results the specific columns requiring repairs were identified and repair details were designed for the columns.

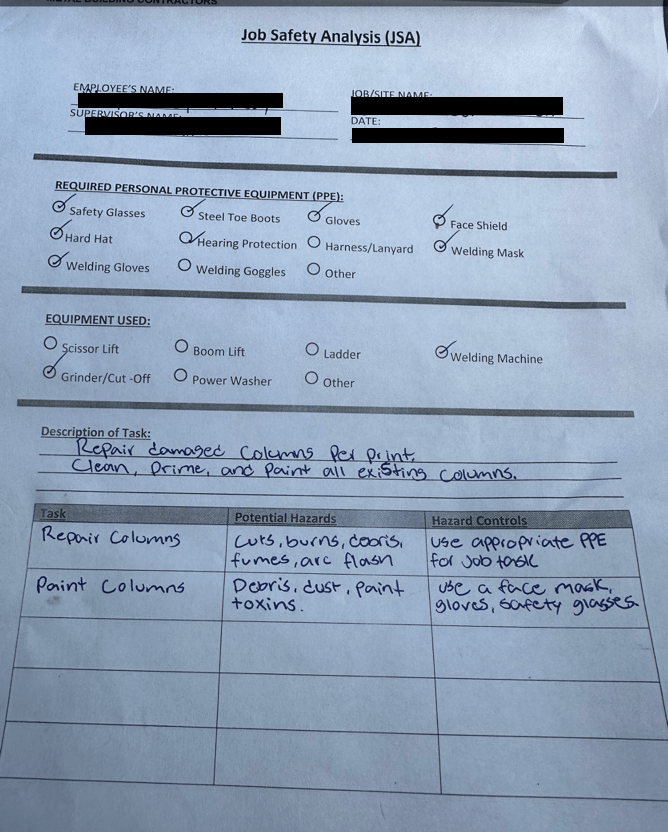

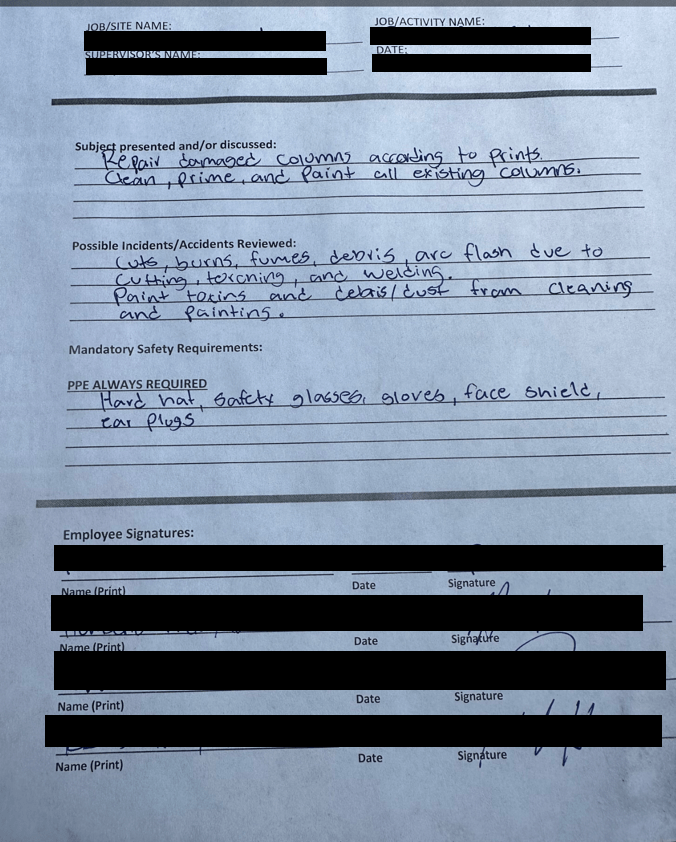

After the engineering was completed, the project began. At the start of everyday a job safety analysis is performed, and a safety plan is finalized. All participants must sign off on the plan and agree to follow the procedures.

This work can be performed safely with very low risk, provided it is properly managed by experienced skilled professionals.

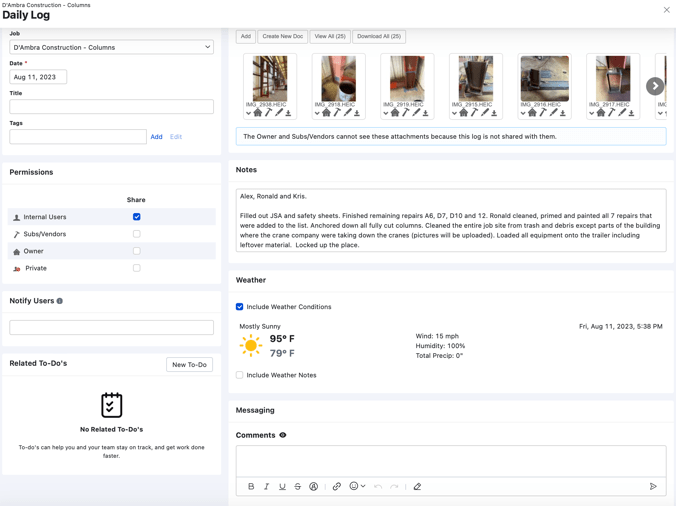

Project Management System – BuilderTrend

These safety documents are reviewed, updated, signed off, and uploaded every day into our project management system. The documents, notes and pictures are available to building owners for viewing. This can also be used to ask questions or make requests.

Normally on a repair of this type, the details call for plates to be welded over the seams. Because of the horizontal bracing this was not necessary.

Cleaning the Columns – If the columns are dirty or have heavy corrosion the columns are cleaned. Typically, pressure wash first, then we use Needlers to find any hidden defect or to prepare for working with the steel. Needlers and guns that have many pieces of needle shaped steel that reciprocating, they are powered using an air compressor.

Shoring and Removing